December 2025 Blog

While exam season limited the amount of time the team could spend together, it didn’t stop progress on the car’s development. From the impact attenuator at the front of the car to the battery in the rear, and everything in between, the car’s development has continued to move forward.

As we look ahead to the winter semester, we will be holding recruitment meetings during the first two weeks of the term. All interested students from any UNB faculty are welcome, with great opportunities available within our engineering, business, and marketing sub-teams.

The team is made up of many exceptional students who have helped advance the car to this point, and we can not wait to welcome new faces in 2026!

Powertrain

December marked an important milestone for the Electrical sub-team as several key decisions and developments moved our EV program forward.

First, we’re excited to share that our high-voltage battery decision is now finalized. After extensive evaluation and discussion, we will be moving forward with a 453.9 V, 7.97 kWh battery pack from Topattery. This configuration meets our performance targets while aligning with our packaging and safety requirements. At this stage, the remaining step is to finalize the payment process so manufacturing can begin.

On the controls side, we have officially received our Vehicle Control Unit (VCU). The team has started familiarizing itself with the hardware and documentation, gaining an understanding of its inputs, outputs, and overall role within the vehicle architecture.

Finally, significant progress has been made on the organizational front. Many new tasks have been created on the low-voltage side, helping us better structure upcoming work related to sensors, wiring, safety systems, and controls integration.

On the drivetrain side, work was completed to define the car’s optimal gear ratio. Further developments were made in the design of the rear axle and differential configuration. In addition, initial designs were created for how the differential would be mounted to the chassis.

Chassis

This past month the chassis team has continued to make progress towards a complete and ready to manufacture design.

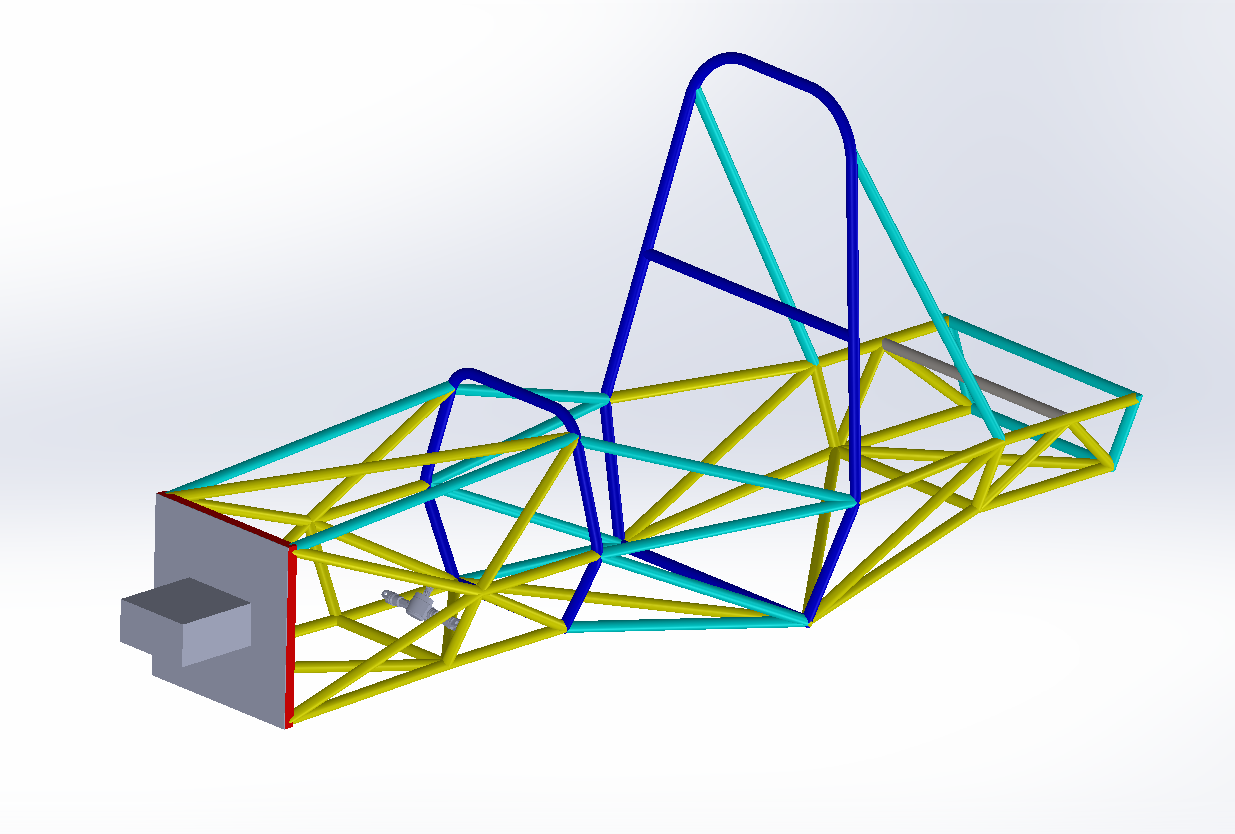

Figure 1. CAD model depicting our current chassis design including the impact attenuator at the front

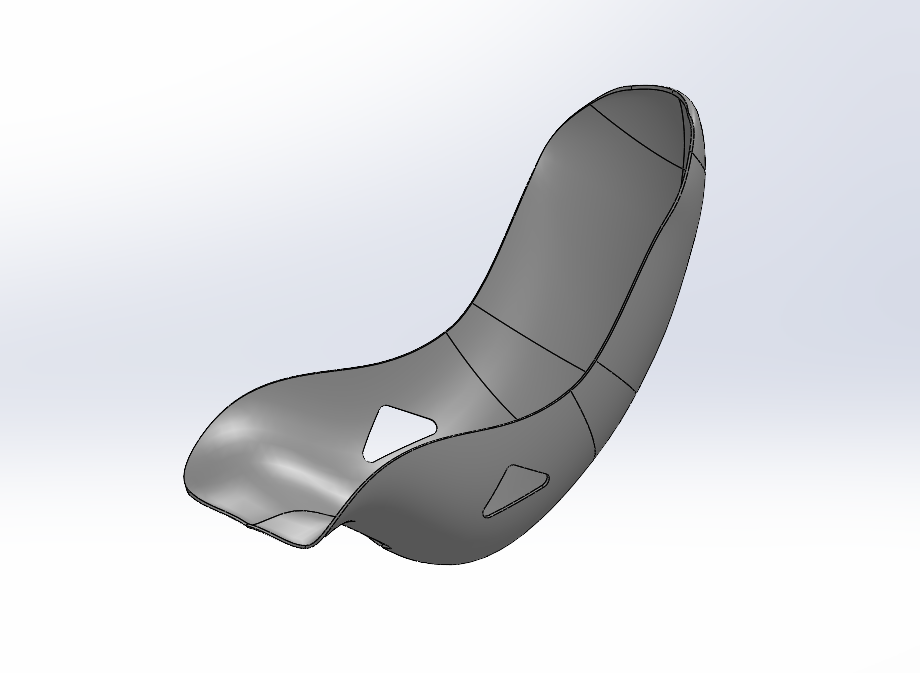

Along with the dynamics team, the rear suspension geometry has been finalized and pick up points have been integrated into the frame. On the side of ergonomics, an initial seat has been designed and integrated into the frame of the vehicle. This design meets the determined driver position and body angles. The team is getting familiar with the ansys software to be able to analyse the strength of the current design and determine what changes need to be made.

Figure 2. CAD model depicting our current driver seat design

With the battery and other components chosen the chassis team will work towards mounting and packaging all components in the rear of the vehicle. This will be the last step in finalizing the dimensions and geometry of the steel tubing so that it is ready to be cut and assembled.